It’s an obvious fact: safe and clean pumping is better than dangerous and messy pumping. But if you want more proof, here’s a quick look at what makes S&L EVERLAST™ Wet Well Mounted Pump Stations superior to submersible pumps.

Confined Space

– Eliminates the need to enter confined space for maintenance or operation.

– Eliminates the need for a valve vault.

Pathogen Exposure

– Exposure to pathogens is limited with S&L stations.

– Release the vacuum & wastewater falls back into the wet well, un-screw 4 bolts, hang the rotating assembly from the lifting stanchion to access the mechanical seal.

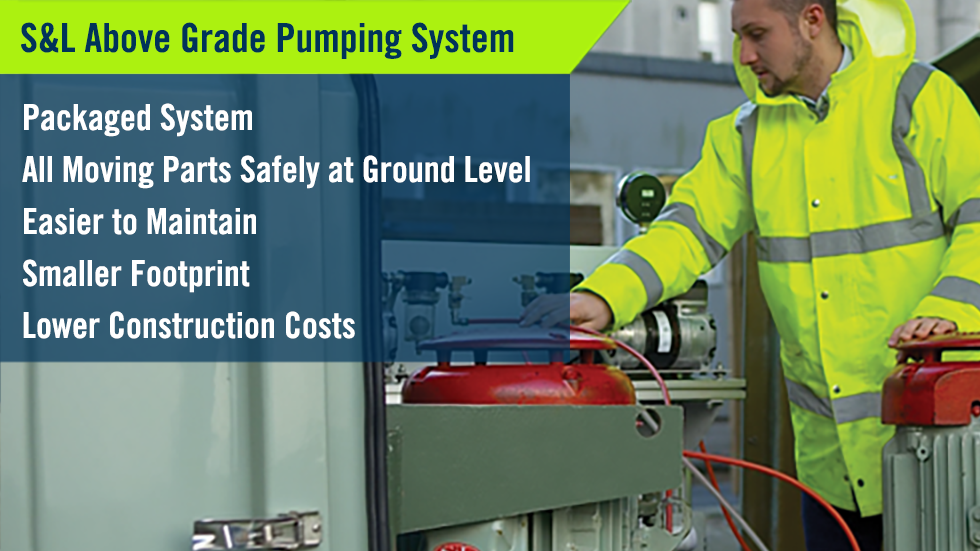

Footprint

– Control panel and valves are located under the enclosure.

– No valve vault is required.

Valve Vault

– No valve vault needed – all discharge valves come preassembled and tested at the factory, under the hood.

– All maintenance & inspection of valves done at-grade.

Fewer Priming Mechanisms

– Submersibles require the following to be primed:

– placement inside wet well at bottom of the wastewater

– explosion proof motor

– oil filled motor

– cables & connections rated for hazardous area

– 316SS rails

– coupling underwater

– seal leak sensor

– motor overheat sensor

– oil filled seal

– S&L stations require the following for priming:

– WaveStart™ Prime Sensing System

– solenoid valve

– vacuum pump

– vacuum tubing

Long Life

– S&L pumps last 25+ years with regular lubrication and general maintenance.

– Design life of the S&L mechanical seal is 7 years.

Maintenance Savings & Safety

– Roughly $2400/yr savings per station over submersible stations for annual maintenance costs.

– Maintenance can be done above grade, eliminating the need for 3 people on site, paperwork, and time for confined space entry maintenance and inspection.

See How One Municipality Saves 50% over Submersibles with S&L