The Dekalb County Public Works Department services a population of more than 750,000 in the ATL region. Its maintenance department and crew manages hundreds of miles of sewer line and 67 lift stations.

44 of these lift stations are S&L Wet Well Mounted Pump Stations.

The County recently reached out to Smith & Loveless GA for help with one particular S&L station that was experiencing less than ideal pump performance and problematic check valve clogs.

Unclogging the check valve was becoming a labor intensive process, not to mention the messiness and safety concerns for the operators working on the equipment.

Field Service personnel out of S&L GA’s Conyers office performed an on-site assessment of the lift station in question and recommended the RAPIDJACK® Quick Clean Check Valve.

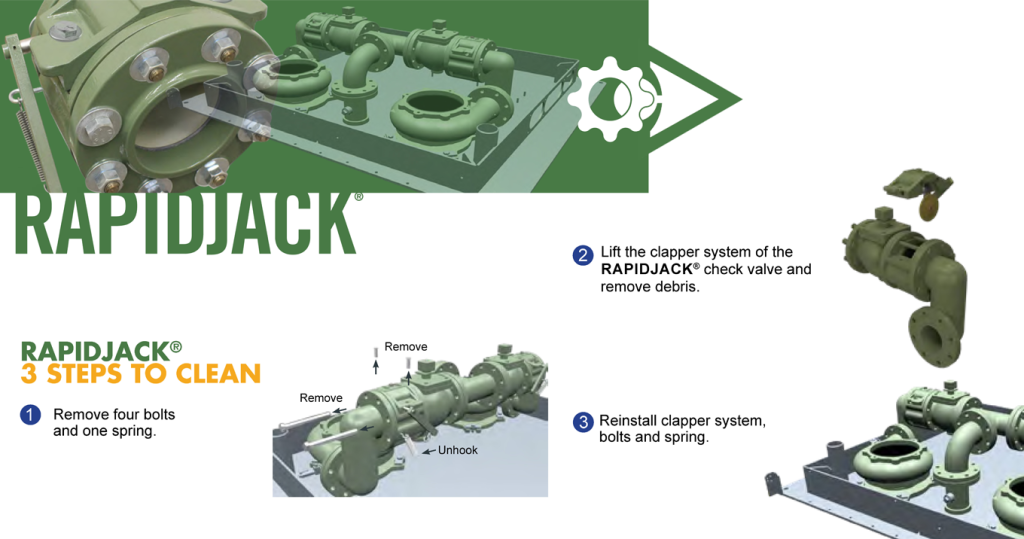

The RAPIDJACK® solves the maintenance issues typically associated with traditional check valve clogs.

Its simple three-step process: remove, clean and replace… allows operators to get back to pumping with ease and without any safety concerns.

Designed for quick removal, just 4 bolts allow the clapper system to be removed while the RAPIDJACK® valve body remains in the piping. Simply remove the obstruction, reinsert the RAPIDJACK® clapper system and the two bolts and go!

This is possible thanks to the improved design that maintains the smaller lay length of a wafer check valve while keeping the valve body in the piping during maintenance, like larger full body check valves.

S&L GA’s field service personnel returned to install the new RAPIDJACK® Check Valve for Dekalb County.

At the time the existing check valve was removed, it had quite the clog building up (as you can see in the image below).

If this sight is a familiar one to you, than you are likely experiencing degraded pump performance and clogging issues as well with your check valve. The RAPIDJACK® may be the answer for you as well.

Inquire here for more information (Tell us you’d like to learn more about RAPIDJACK® in the comments of the form): https://www.smithandloveless.com/pumping-inquiry